How to Use a Soldering Station?

一.What is a soldering station

Soldering station is a multi-purpose power supply soldering equipment specially designed for electronic component soldering. Soldering stations are widely used in electronic repair shops, electronic laboratories and industrial fields. Sometimes it is also used for simple home soldering for hobbyists.

How a soldering station works: Two workpieces are soldered together by applying heat to the solder (usually tin wire) for melting. The temperature control of the soldering station is very important when it is working. However, there are many ways to control the temperature of the soldering station, but the simplest one is the adjustable power control. The soldering station quickly transfers heat to the workpiece through the soldering iron to control the temperature. Another method is to use a thermostat to control the temperature by turning the power on or off. There is also a more advanced solution, which uses an integrated chip to detect the temperature of the soldering iron tip, and then adjusts the power of the thermostat to control the temperature. When the temperature of the soldering iron tip is lower than the set temperature, the host is turned on, and the power is supplied to the thermostat to generate heat. When the temperature of the soldering iron tip is higher than the set temperature, the host is turned off and stops heating. This method has relatively high requirements for soldering personnel, and must be operated by people who know some techniques.

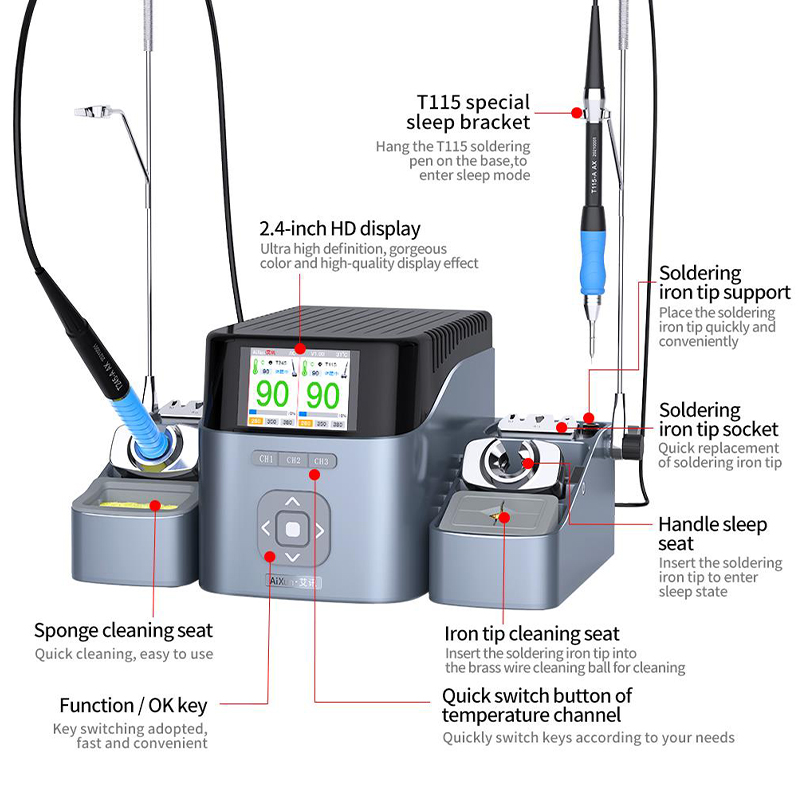

二.Composition of the soldering station

How to Use a Soldering Station

1.Soldering iron handle

The soldering iron consists of insulating material, heating core and soldering iron tip. A soldering iron is a pen that a welder uses to solder on a circuit board. It reconciles solder and flux, and integrates the relationship between various electronic components and circuit boards under precise operation, which can be soldered or desoldered. It is precisely because of its magical effect that a circuit gradually becomes a reality from an idea.

2.Soldering iron tip

The soldering iron tip is the heat-conducting component of the soldering station. The main component of the tip is copper, which accounts for about 85% of the overall material. The good thermal conductivity of copper is conducive to the rapid heating of the soldering iron tip.

3.Soldering iron stand

The soldering iron stand is used to temporarily hold the handle away from flammable materials. The soldering iron stand usually has a wet sponge or a yellow steel ball to clean the impurities from the soldering iron tip.

4.Soldering station

In addition to the stand, it usually comes with a number of other tools that connect to the main unit via transformers, lights, power supplies, and other controls. One or more tools such as soldering iron, heat gun, desoldering gun, infrared heating element, patch thermal tweezers may be provided.That is to say, it is versatile and recommended for complex soldering tasks in electronics labs and electronics repair shops.

三.How to use a soldering station

1) Insert the power cord of the soldering station into the socket and turn on the power switch. At this time, you will see that the temperature number on the display of the soldering station will increase with time, just wait for the temperature to reach between 300°C and 400°C.

2) Adjust the temperature according to the soldering needs. If it is the soldering of plug-in capacitors, the recommended temperature range: 330-370°C, 350°C is the most suitable. If it is the soldering of chip capacitors, 300-320 ℃ is enough. It will also affects the soldering if the temperature is too high. If large components are to be soldered, the soldering temperature should not exceed 380°C.

3) During the soldering process, first tin the upper layer of the soldering tip, then use the soldering tip to heat the solder joints, and then feed the solder.

4) For lines that are difficult to solder, a small amount of flux can be used. Proper use can improve the quality and efficiency of soldering. Rosin can be used appropriately when there are lines that are difficult to solder.

5)Align the components with the parts to be soldered, and pay attention that whether the PCB pads are aligned and whether the functional areas are placed correctly to avoid reverse connection of components. After soldering is complete, wait for a while to see if the components are fully soldered.

(6) In order to ensure that the solder joints are in good contact with the motherboard, use an electric soldering iron to repair the virtual solder joints after soldering, and separate the short circuits.

(7) After the soldering is completed, turn off the power supply, place the tip on the soldering handle, and unplug the power plug when the temperature is zero.

四.Soldering Station Precautions

Pay attention to the following points when using the hot air soldering station:

- The ground wire must be connected to avoid static electricity.

- Do not touch the tip of the soldering iron and its surrounding metal parts.

- Do not use a soldering iron tip near flammable objects.

- Make a “safety sign”. Soldering iron tip is very easy to burn, which may cause dangerous accidents.

- Turn off the power during breaks or after work. (Soldering iron idle for more than 30 minutes)

- Turning off the power and wait for the soldering iron tip to cool before replacing parts or installing a soldering iron tip.

- Please put the handle on the stand when not in use to prevent other problems after touching it.

- Remember to tin on the surface of the tip for the convenient for next use.

Leave a Reply

Want to join the discussion?Feel free to contribute!